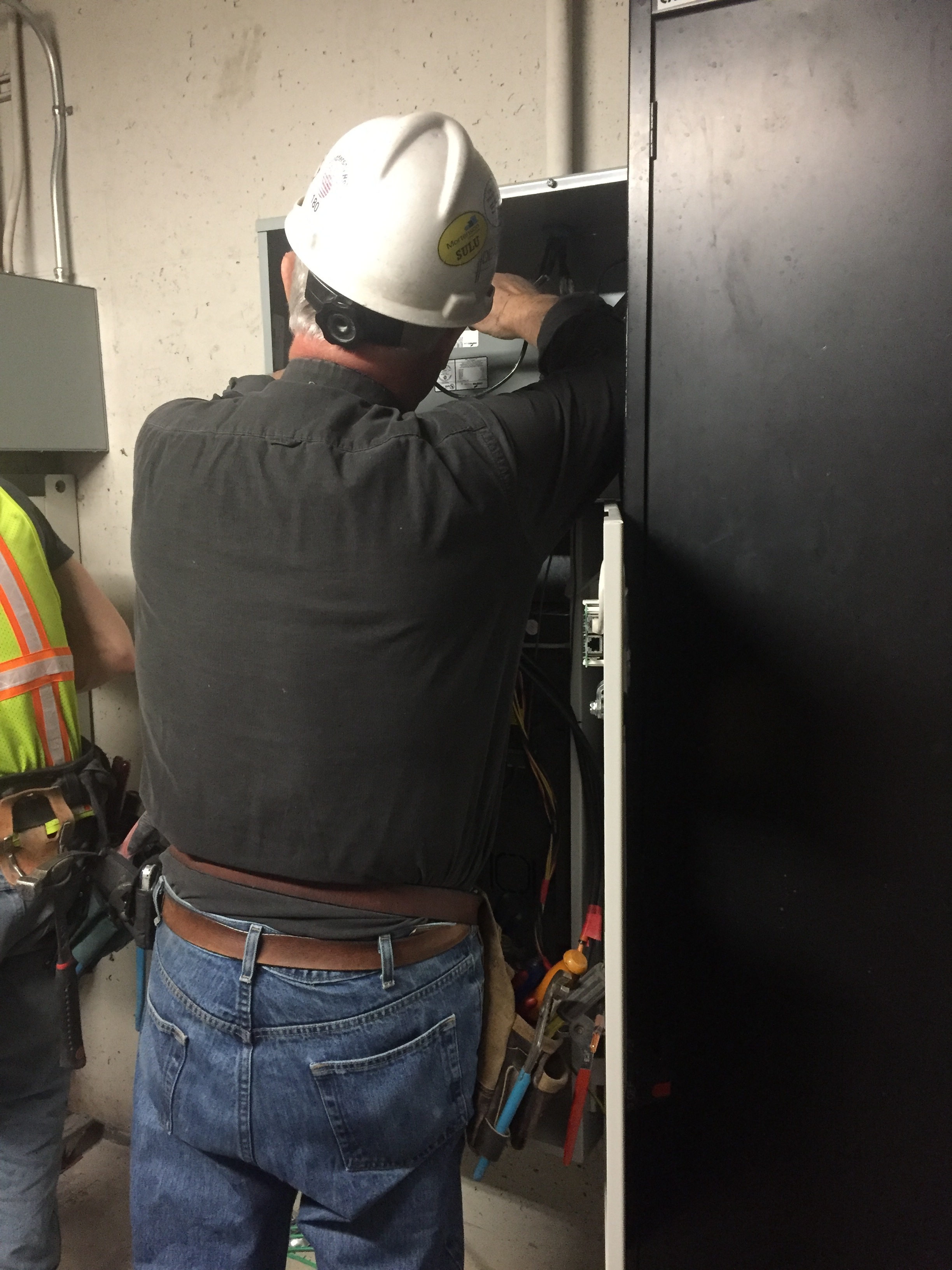

The purpose of this project was to perform VFD upgrades to six pumps and replacement of one defective VFD. Existing equipment was removed and disposed of. New equipment was installed and training for chiller plant personnel was provided upon installation.

Crack Seal Parking Areas- Grand Junction, CO

The purpose of this project was to apply a bitimous surface treatment to the existing asphalt pavement in order to extend the life of the existing asphalt pavement and to provide a safer walking surface for pedestrians. Existing asphalt was cleaned of loose debris and cracks were treated with herbicide, filled with cover coat material (chips) and firmly tamped to provide a smooth surface for the surface treatment. A two-layer surface treatment was then applied along with a fog seal finish to minimize chip throw. Area receiving surface treatment amounted to approximately 232,000 SF.

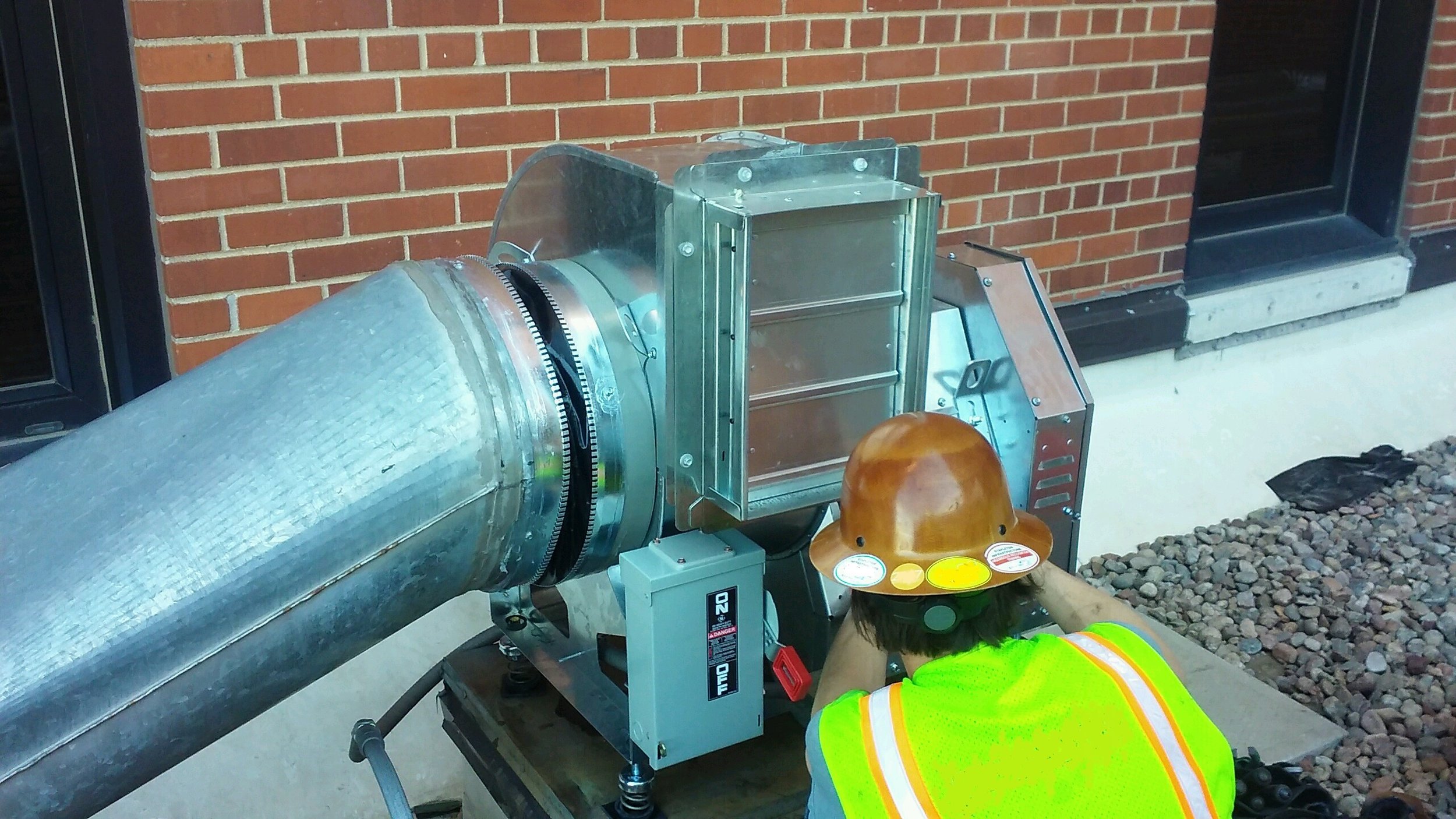

DVA Exhaust Fan- Denver, CO

This project installed a new exhaust duct system in Building A, Rooms A1-124 & A1-353, to vent out fumes created by the elevator mechanical systems. Work involved installation of a new exhaust duct work in room 10-01-C7-01 to remove up to 450 cfm from the room. This was achieved by tapping into the existing 12x12 exhaust duct in the space with a 10x10 branch and three 8x8 or 8” dia branches pulling air from near each of the three elevator equipment cases. New exhaust duct work in room 10-01-C9-02 to remove up to 150 cfm from the room was also performed by tapping into the existing 10x10 exhaust duct above room 10-01-C9-10 with an 8x8 or 8” dia branch duct pulling air from near the elevator equipment case. Lastly, a cut was made into the existing wall to create a path for the new exhaust duct and path and repair the wall to maintain the existing rated wall.

Lab Biohood Upgrade- Grand Junction, CO

This project replaced the existing Clinical Laboratory bio-hood in Building 1 of the Grand Junction VAHS, Grand Junction, CO. Work involved the demolition and removal of the existing bio-hood, and replacement with a new 540-400 hood. Abatement and demolition of approximately 25 lineal ft of 8- inch galvanized bio-hazard spiral duct was performed. Additional work included repair to 3 concrete structural floor penetrations, refurbishing of suspended acoustical ceiling, flooring, and painting of construction areas.